How They Do It: Making a Plumbus

Ever wondered how they make Plumbuses? Today, we’ll take you through the intricate manufacturing process of everyone’s favorite household device. Please note that this is for educational purposes only – Plumbus manufacturing should only be attempted by certified professionals.

The Manufacturing Process

1. Initial Preparation

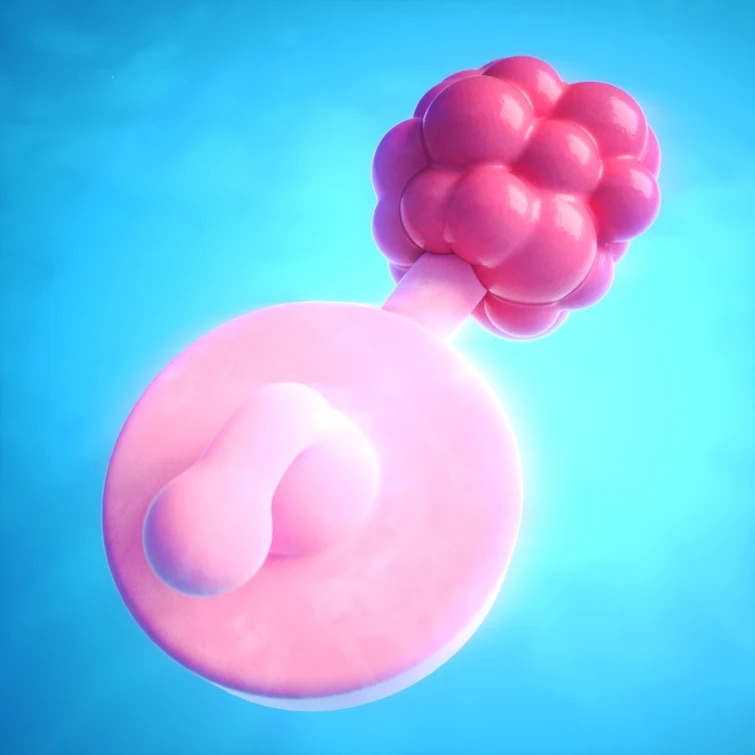

- First, they take the Dinglebop

- The Dinglebop is then smoothed out with a bunch of Schleem

- The Schleem is later repurposed for other batches

2. Core Processing

- Push the Dinglebop through the Grumbo

- Where the Fleeb is rubbed against it

- It’s important that the Fleeb is rubbed, as the Fleeb contains all the Fleeb juice

3. Critical Steps

- Several Hizzards are in the way

- The Blamfs run against the grooved side

- This ensures proper plumbing of all layers

4. Final Assembly

- Regular Schlami shows up

- Rubs it, and spits on it

- Schlami application is crucial for quality control

- Final cutting of the Plumbus occurs

- Excess Grumbo is removed

Quality Control

Certification Requirements

- Quantum stability testing

- Fleeb juice concentration analysis

- Dimensional resonance verification

- Schlami approval rating

Safety Measures

- Protective quantum shielding

- Temporal stabilization fields

- Certified Schlami supervision

- Fleeb containment protocols

Common Manufacturing Mistakes

-

Insufficient Fleeb Contact

- Results in unstable quantum matrix

- Poor dimensional alignment

- Reduced functionality

-

Improper Schlami Treatment

- Compromised integrity

- Irregular Fleeb distribution

- Quantum desynchronization

-

Grumbo Misalignment

- Structural instability

- Reduced efficiency

- Temporal drift

Industry Standards

All legitimate Plumbus manufacturers must:

- Hold Galactic Federation certification

- Employ certified Schlamis

- Maintain pure Fleeb sources

- Follow quantum safety protocols

Remember: Always verify your Plumbus’s manufacturing credentials before purchase.